Refrigeration is used to keep food and drink fresh longer and to preserve temperature-sensitive chemicals. It also keeps perishable goods cold during shipment and storage.

In homes and businesses, All Temp Air Conditioning & Refrigeration enable people to store foods in their kitchens, offices, and restaurants. It also allows for the long-distance transportation of fresh produce, meats, and other foods.

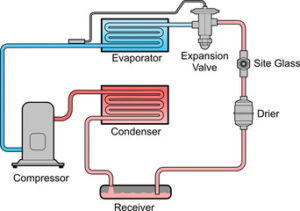

Refrigeration Cycle

Refrigeration is the artificial cooling of a space, substance, or system by absorbing and rejecting heat. The refrigeration cycle involves four basic components: the compressor, condenser, expansion device, and evaporator.

The refrigerant fluid, usually a gaseous liquid such as R134a in a household refrigerator or chiller, enters the compressor. The compression process boosts the pressure of the refrigerant to very high levels. The high temperature and the high pressure cause the gas to liquefy, changing its state from a gas to a low-pressure liquid. The refrigerant then flows into the condenser, a coil of copper tubing with metal fins and fans to passively cool the refrigerant. The condenser is also an air-cooled device because it depends on the ambient air to remove the rejected heat from the refrigerant. The cooling of the refrigerant in the condenser causes it to change from a liquid back to a gas, and this changes its state again.

As the refrigerant reaches the end of the coils in the condenser, it reaches a point called the metering device. The metering device is a restriction that restricts the flow of refrigerant into the evaporator, or it may be a thermal expansion valve or capillary tube. The metering device regulates the amount of refrigerant flowing into the evaporator, depending on equipment size and the application.

The evaporator is similar to the condenser in that it contains a coil of tubes with fins and fans. The purpose of the evaporator is to absorb heat from the air that passes over the coil (blown by fans), changing the low-pressure liquid refrigerant back into a gas and allowing it to expand. As it expands, the refrigerant takes in the absorbed heat from the environment and changes its state again, returning to a cold liquid in the evaporator and continuing the cycle. The refrigeration cycle is what allows us to store food in a cold liquid form and enjoy fresh food much longer than before the invention of mechanical refrigeration. Refrigeration has revolutionized the way we live, enabling us to enjoy foods such as dairy products and meats that were once only available at very high prices or even unavailable in our homes. Refrigeration in transit has made it possible to ship and sell fruits, vegetables, and other food from distant places that would have been too expensive or too fragile to reach our markets otherwise.

Refrigeration Components

Refrigerators have come a long way since their creation in the 1800s, but their basic function has not changed. The four main refrigeration components are compressors, condensers, evaporators, and expansion devices. Having these working properly is vital to your business’s refrigerators’ ability to serve their purpose.

Compressors are the heart of any refrigeration system, as they are responsible for moving refrigerant around the unit and determining its overall temperature. There are two different types of compressors: reciprocating and rotary screw. Reciprocating compressors use pistons to move the refrigerant through a system of valves and chambers while rotary screw compressors use rotors with blades to create pressure differences that drive the movement of the refrigerant.

The next component in the refrigeration cycle is a condenser, which removes heat from the refrigerant. This is done by transferring the heat of the products stored inside the fridge to the refrigerant, causing it to evaporate. The vapors from the evaporator then travel back to the compressor to be recompressed and cooled, creating the refrigerant’s heat exchange.

After the compressor has recompressed and cooled the refrigerant, it is passed through an expansion valve. This device controls the flow of the liquid refrigerant by opening and closing based on the load requirements. This helps to prevent overcharging and undercharging of the refrigerators’ refrigeration system, which can cause damage.

The expansion valve also has a “pressure limiting” component known as a capillary tube. This is a length of narrow tubes that restricts the flow of the refrigerant but is still much smaller than the expansion valve’s opening. The most common type of expansion valve is a thermostatic metering device or TEV. This uses a bulb that is partially filled with refrigerant and strapped to the pipe work exiting the evaporator, which senses the heat of the vapor leaving and through pressure can open and close to vary the amount of vapor entering the evaporator.

Increasing the energy efficiency of your refrigeration units can have several benefits for your business, including reducing energy costs and carbon footprint, saving money, and preserving foods for longer. Refrigeration units that utilize energy-efficient compressors and Smart temperature controls can make a big difference in your business’s operations and help you comply with environmental regulations.

Refrigeration Safety

Refrigeration is a great way to preserve food for longer periods, but it doesn’t eliminate the risk of bacterial contamination or chemical spoilage. Rather, refrigeration slows down the growth of bacteria so that the food is safe for consumption. It also preserves the food’s organoleptic properties and extends its shelf life. The main foodstuffs that require preservation at temperatures slightly above 0°C are matured cheeses, drinks (beer, wine, fruit juice, soft drinks), and cold meats.

In general, the higher the temperature, the faster the deterioration of food. Therefore, it is important to keep refrigerated foods at a constant and stable temperature. This way, the microbial growth is kept to a minimum and the quality of the products is maintained.

When it comes to refrigeration safety, several measures need to be taken into account. The most obvious measure is the use of appropriate equipment when handling refrigerants. This includes protective gloves, eyewear, and a respirator mask.

In addition to this, it is important to follow defined procedures when inspecting, servicing, or repairing refrigeration equipment. This will help prevent accidents and save on repair costs. It is also important to understand that flammable gases are dangerous and should only be handled by trained personnel.

Another aspect of refrigeration safety is to avoid cross-contamination. This can be done by storing raw foods separately from ready-to-eat foods and never leaving food out of the fridge for more than two hours. It is also important to keep refrigerators clean and to store them at a constant temperature.

For facilities that use ammonia refrigeration, it is vital to have a response plan in case of an emergency. This includes having a refrigeration safety awareness specialist who is capable of shutting down the plant and evacuating staff if necessary. The specialist should also have access to a mobile phone and be familiar with all fire and evacuation protocols.

Refrigeration Maintenance

Having a refrigeration preventative maintenance checklist in place can help reduce downtime and increase the life of your equipment. It can be the difference between a minor inconvenience and a costly breakdown.

It’s important to keep the interior of your refrigerator and freezer clean to remove any dirt or debris that may interfere with airflow and heat transfer. You should wipe down the shelves and surfaces every week to prevent food spills, which can lead to bacterial contamination. Check for gaskets to make sure they are not split, cracked, or worn down. You should check these more often if your unit is in a kitchen that uses grease, as the excessive moisture from this can wear down the gaskets faster.

A poorly maintained refrigeration system will work harder to maintain its temperature, which drives up energy costs. Dirty condenser coils, clogged drain lines, and refrigerant leaks are some of the most common problems that need to be corrected to avoid higher energy bills. During regular maintenance visits, these issues can be caught and resolved before they cause the equipment to shut down.

Another common problem is an improperly sized defrost thermostat. This can lead to a defrost cycle that takes too long, which leads to the equipment running inefficiently. A properly sized thermostat will ensure that the defrost cycle runs as it should, keeping the fridge at a constant temperature.

Refrigeration preventative maintenance should also include cleaning the condenser coils regularly to remove any dirt, dust, lint, or other debris that might restrict heat transfer. You should also lubricate all moving parts using proper lubricant, as recommended by the manufacturer.

It’s also a good idea to check the drain pan and tubing for any build-up of debris or food particles that may cause an overflow. You should also wipe down the drip tray to remove any food residue that could potentially contaminate the refrigeration system.

The final step in refrigeration preventative maintenance is ensuring that the door gaskets are in good condition and not cracked or warped. This is an easy and inexpensive repair that can improve the functionality of your refrigeration system by making it easier to access and close the doors. You should also check that the refrigerator light shuts off when you close the door. A light that doesn’t turn off can generate excess heat, causing the refrigerator to work overtime to maintain its set temperature, which will drive up your energy costs.